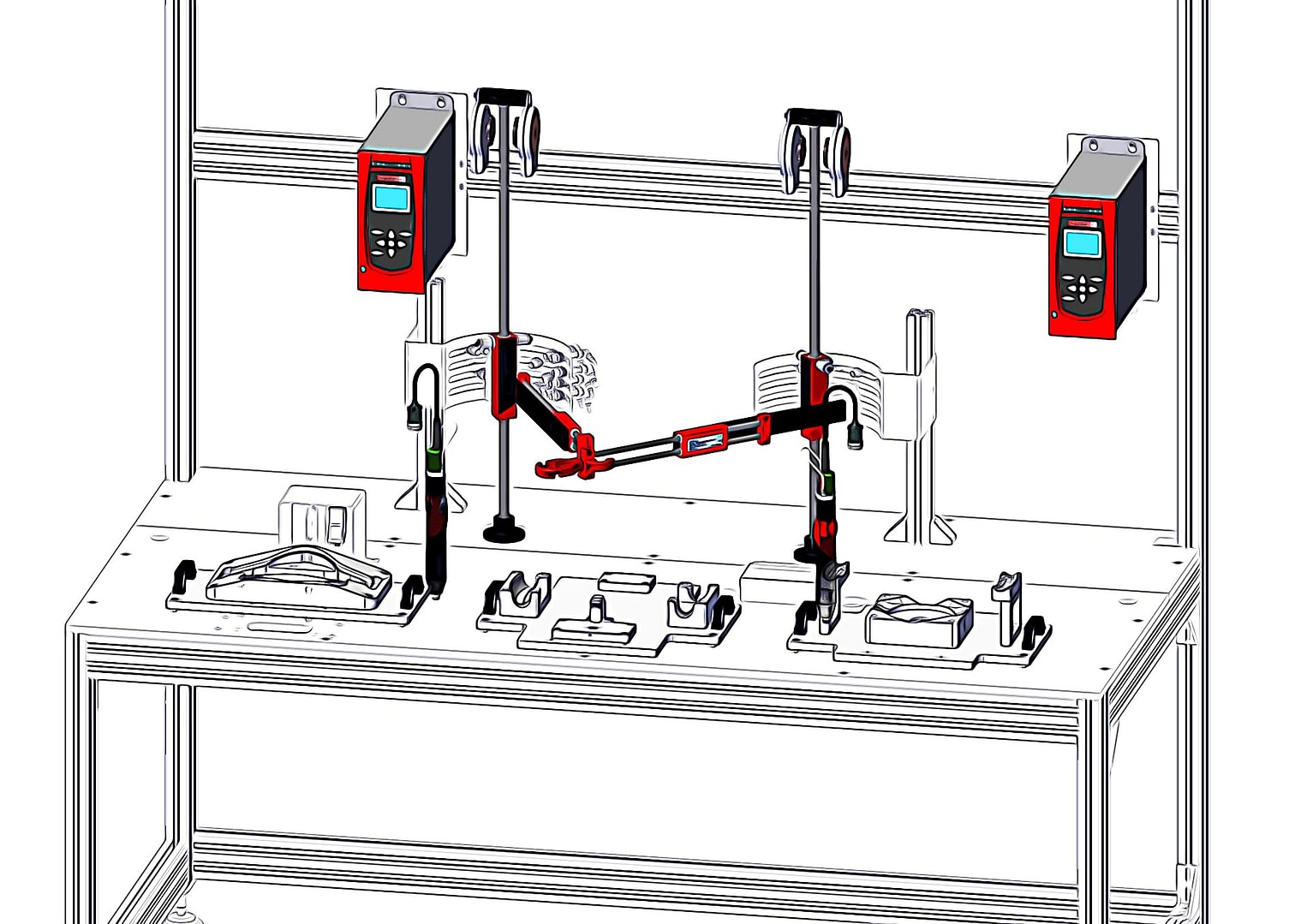

Imagine a workstation where precision, flexibility, and human expertise come together to enhance efficiency in industrial manufacturing.

A Manual Station is a semi-automated workstation designed to support operators in performing assembly, quality control, and specialized processes with enhanced precision and efficiency. These stations integrate ergonomic design, guided workflows, and smart tools to ensure repeatability, safety, and ease of use in production environments.

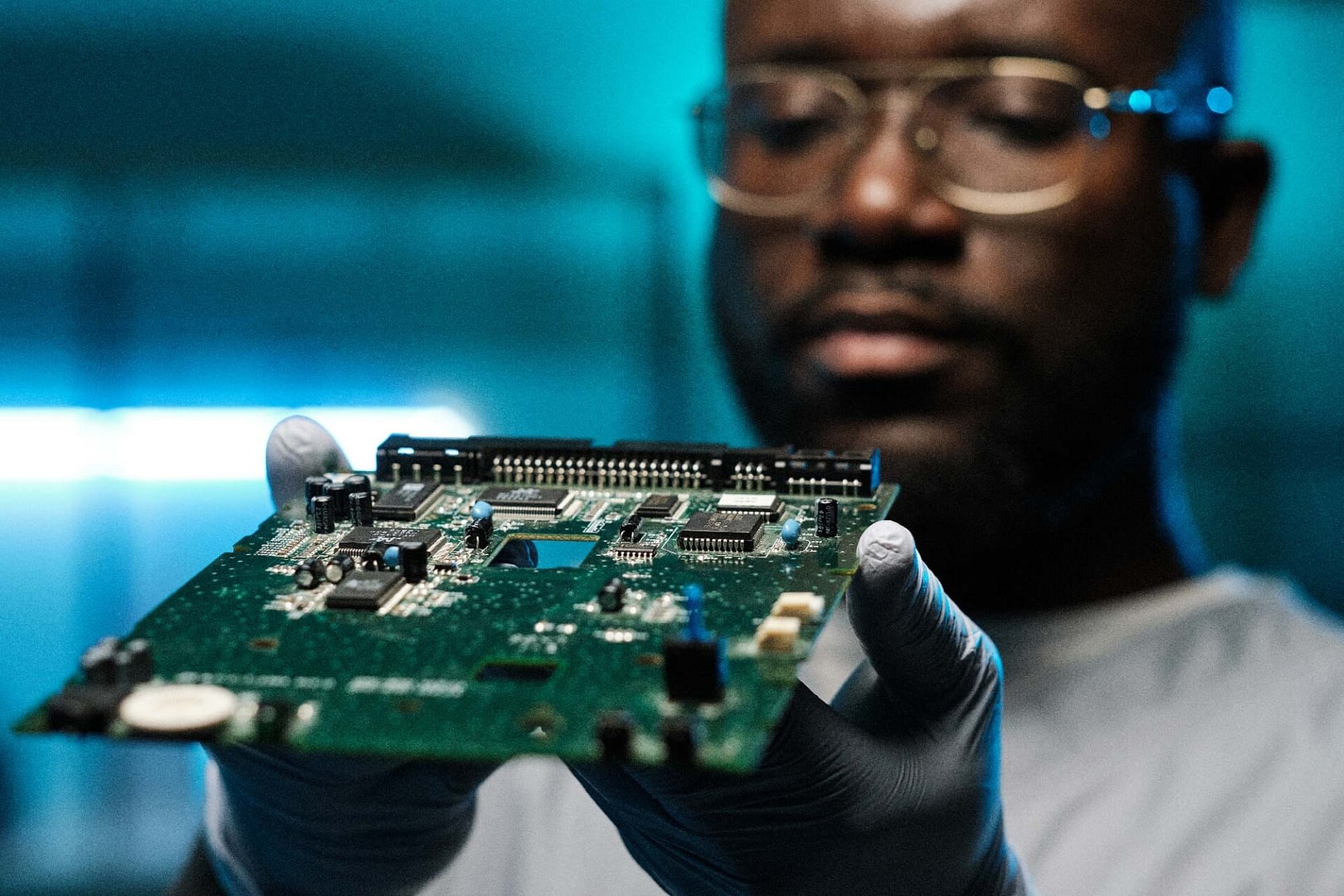

Unlike fully automated systems, Manual Stations provide the flexibility of human decision-making while incorporating technology to assist with complex or delicate tasks.

Combines human expertise with tool-guided assembly for optimal accuracy.

Designed for operator comfort, reducing fatigue and increasing productivity.

Requires minimal infrastructure changes and easily integrates into existing production lines.

Ideal for low-volume, high-variability assembly operations.

Can be later upgraded with collaborative robots (cobots) or automation modules.

The Line with Pallet Conveyors is particularly well-suited for the following industries and applications:

Assembly of small mechanical components.

Circuit board assembly with guided torque tools.

Fine-tuned manual adjustments for surgical tools and prosthetics.

At GAV Sistemi, we design custom Manual Stations tailored to your specific production needs. Each workstation is meticulously engineered to enhance operator performance while integrating seamlessly into existing workflows. Our approach focuses on creating ergonomic designs that prioritize operator safety and efficiency, incorporating custom tooling and fixtures to match precise component specifications.

Guided workflows with visual indicators and feedback mechanisms ensure accuracy and consistency in every task. Additionally, our Manual Stations are designed with scalability in mind, allowing seamless integration with collaborative robots and digital monitoring systems for future automation.

By merging operator expertise with intelligent workstation design, we enhance precision, efficiency, and reliability across production environments.

Manual Stations by GAV Sistemi enable a wide range of specialized operations, ensuring precision and flexibility in manual assembly environments.

Learn about all the new and exciting leaps in automation we’re making.

© GAV Sistemi S.r.l. - P.IVA 01861100608 - N. REA 106700 - Via Tumuli 4/a , FR 03100 Italy

Built by Dopamina