Imagine a testing system that ensures airtight integrity, detecting even the smallest leaks in sealed components with unmatched precision and efficiency.

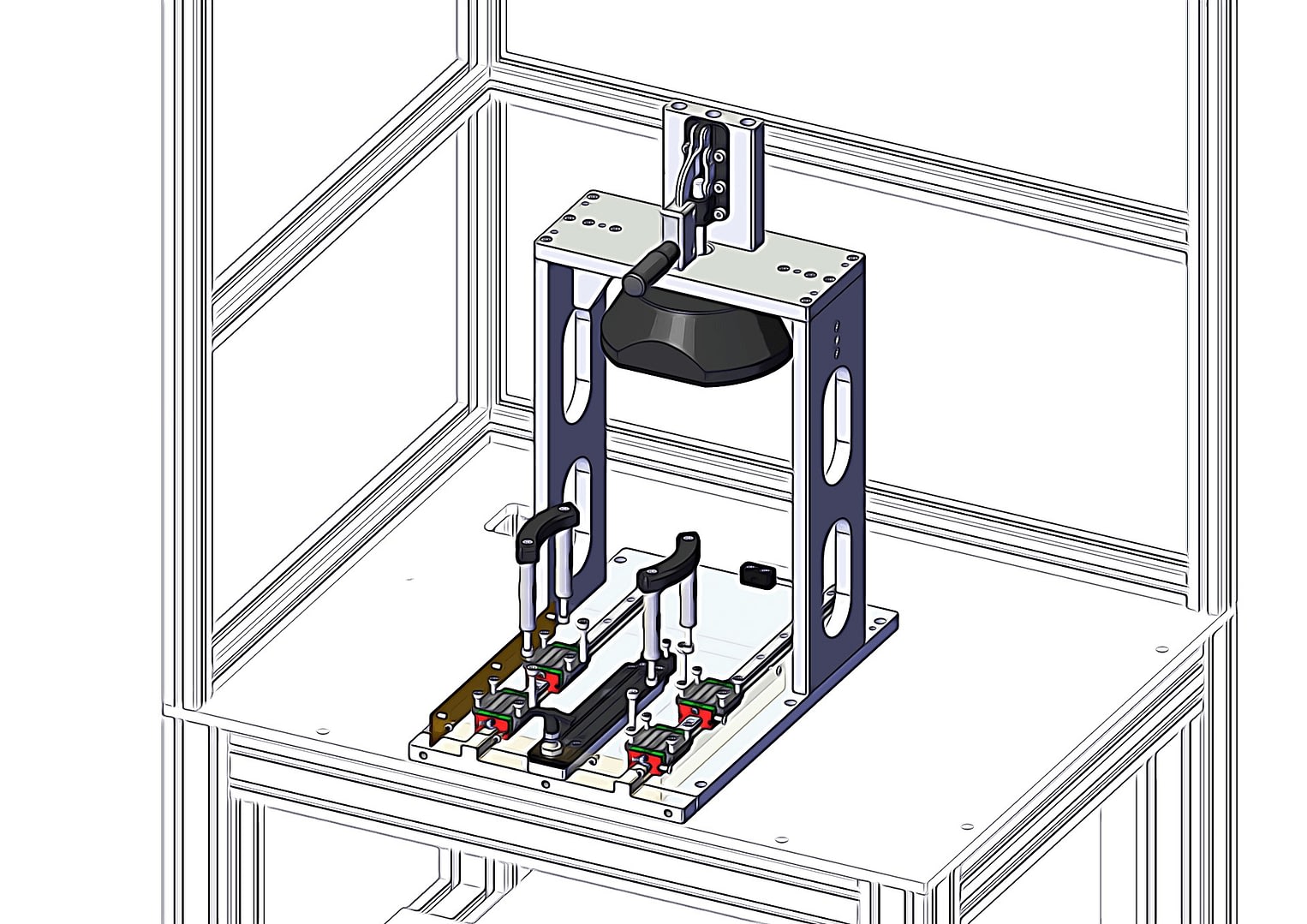

A Leak Test Machine is an automated system designed to verify the airtightness of sealed components by detecting micro-leaks that could compromise performance, safety, or compliance.

Using high-precision sensors and advanced testing methods such as pressure decay, vacuum testing, or tracer gas analysis, these systems provide non-destructive, real-time testing to ensure each product meets the highest quality standards.

Leak test automation eliminates human error, optimizes production workflows, and enhances overall reliability, making it a critical component in industries where sealing integrity is non-negotiable.

Identifies micro-leaks using advanced pressure, gas, and vacuum testing technologies.

Ensures safety and compliance by eliminating defective components.

Minimizes scrap and rework by identifying leaks early in production.

Easily connects to existing production lines and quality control systems.

The Line with Pallet Conveyors is particularly well-suited for the following industries and applications:

Testing of fuel systems, brake components, cooling circuits, and airbag inflators.

Testing heat exchangers, pipelines, and sealed ducting systems to ensure efficiency and safety.

Validation of syringes, catheters, and fluid delivery systems for sterility and leak-proof performance.

Ensuring airtight and vacuum-sealed containers for food, pharmaceuticals, and chemicals.

At GAV Sistemi, we understand that each production line is unique. That’s why every project begins with an in-depth feasibility study to analyze product dimensions, material behavior, cycle time requirements, and regulatory standards.

A Laser Marking system can be configured to handle a wide variety of tasks, typically involving high precision and repeatability. GAV Sistemi’s systems often integrate several of the following operations in a single, compact setup:

Learn about all the new and exciting leaps in automation we’re making.

© GAV Sistemi S.r.l. - P.IVA 01861100608 - N. REA 106700 - Via Tumuli 4/a , FR 03100 Italy

Built by Dopamina