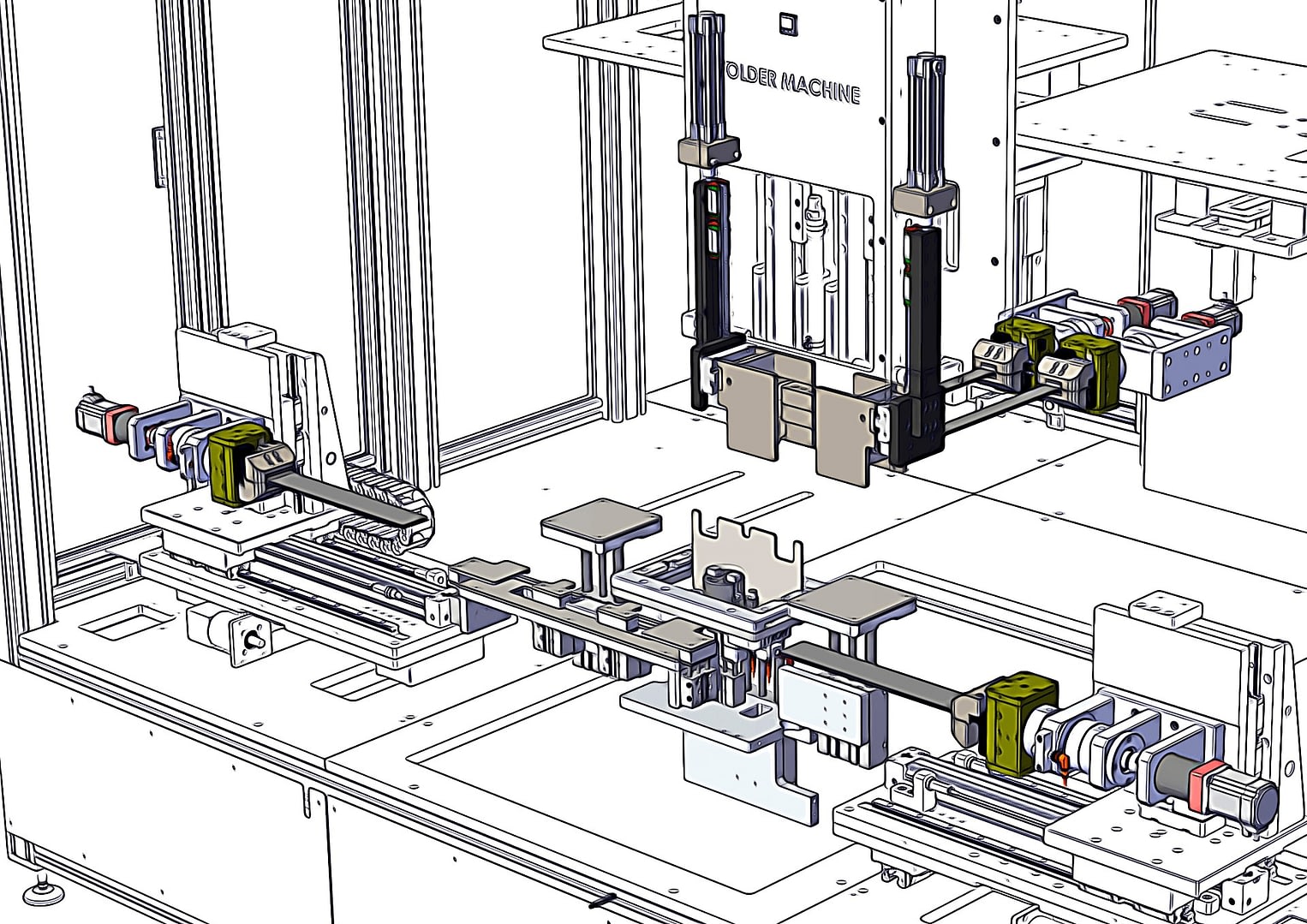

Airbag Folder Machine

Imagine an automated system that ensures the precise folding and packaging of airbags, optimizing their storage space and guaranteeing flawless deployment in case of activation.

What Is an Airbag Folder Machine?

The Airbag Folder Machine is an advanced automated solution designed for the accurate folding and packaging of airbags before installation in vehicles. This system ensures uniform folding, minimizing the space occupied by the airbag in its housing module while ensuring proper deployment during activation.

This machine eliminates the inconsistencies of manual folding, improving both product safety and production efficiency. According to industry standards, automated systems like the Airbag Folder Machine can significantly reduce errors and improve the reliability of airbag performance during critical situations.

Executes operations with superior speed and precision compared to manual processes.

Reduces the need for direct labor, lowering production costs.

Achieves high precision through advanced sensors and automated controls.

Integrates a system for real-time parameter control and data recording.

Compact configuration compared to traditional production lines.

Includes isolation mechanisms to protect operators during operation.

Ensures accurate mechanical control for high-quality processing.

Allows the addition of modules with diverse functions to adapt to new needs.

Can be connected to existing production lines without significant modifications.

Industries and Applications

The Robot Station is particularly well-suited for the following industries and applications:

Production and assembly of airbags for vehicle safety systems.

GAV Sistemi’s Tailored Solutions

At GAV Sistemi, we understand that every production line presents unique challenges. For this reason, every project begins with an in-depth feasibility study aimed at clarifying the specific requirements of the client. This process includes analyzing product dimensions, desired cycle times, quality control demands, and applicable regulatory standards. Our team works closely with you to design customized solutions that integrate seamlessly into your existing workflows, ensuring maximum efficiency and tangible results.

Below are the key points that guide the design of our solutions, reflecting our commitment to innovation, quality, and sustainability:

Integration with Other Machines

Personnel Reduction

Advanced Programming

Energy Efficiency

Remote Monitoring

Industry 4.0 Compatibility

Modularity and Scalability

Reliability and Safety

Possible Operations

An Airbag Folder Machine can be configured to handle a wide variety of tasks, typically involving high precision and repeatability. GAV Sistemi’s systems often integrate several of the following operations in a single, compact setup:

Automated Folding

- Precise configuration of airbags to ensure optimal storage and deployment.

Compression and Fixing

- Securing the folded airbag for subsequent insertion into the housing module.

Quality Inspection

- Verification using optical and pressure sensors to ensure folding conforms to strict standards.

Traceability and Data Recording

- Association of each airbag with a serial code for production monitoring and quality assurance.