Imagine an assembly process that ensures high-strength, tool-free connections, eliminating the need for welding, adhesives, or threaded fasteners.

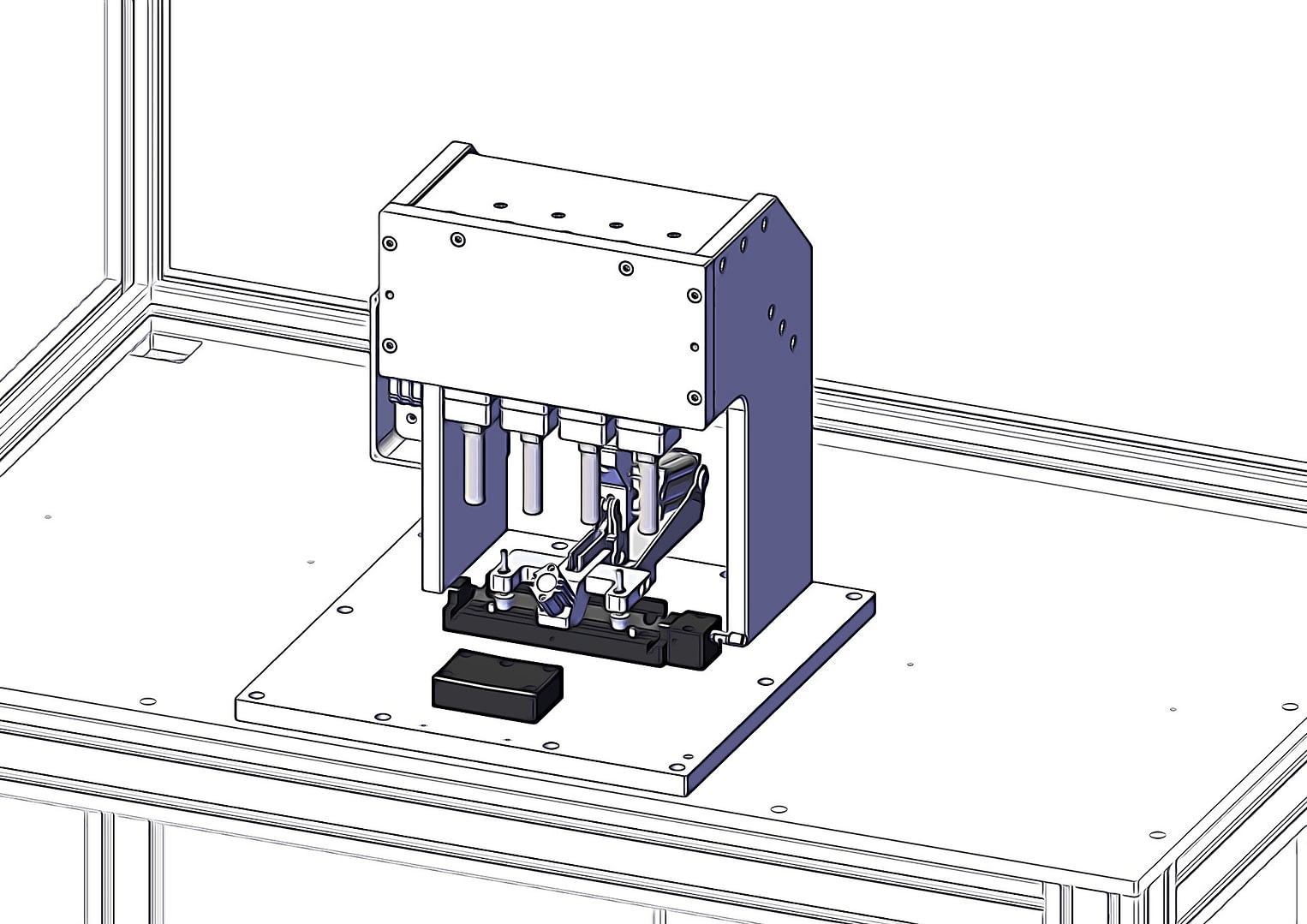

A Press Fitting Machine is an automated system designed to assemble mechanical components by applying controlled force to create a secure, permanent connection without welding, screws, or adhesives.

This technology is widely used in precision engineering where strong, repeatable, and high-precision joints are required. By automating the press fitting process, manufacturers can increase efficiency, reduce production costs, and ensure consistent assembly quality.

Creates robust, vibration-resistant joints without thermal stress.

Eliminates consumables such as screws, adhesives, or welding materials.

Optimized cycle times for high-volume manufacturing.

Ensures consistent press force and positioning for every assembly.

No emissions or chemical residues, making it a sustainable alternative to traditional assembly methods.

The Line with Pallet Conveyors is particularly well-suited for the following industries and applications:

Assembly of bushings, bearings, and shafts in drivetrain components.

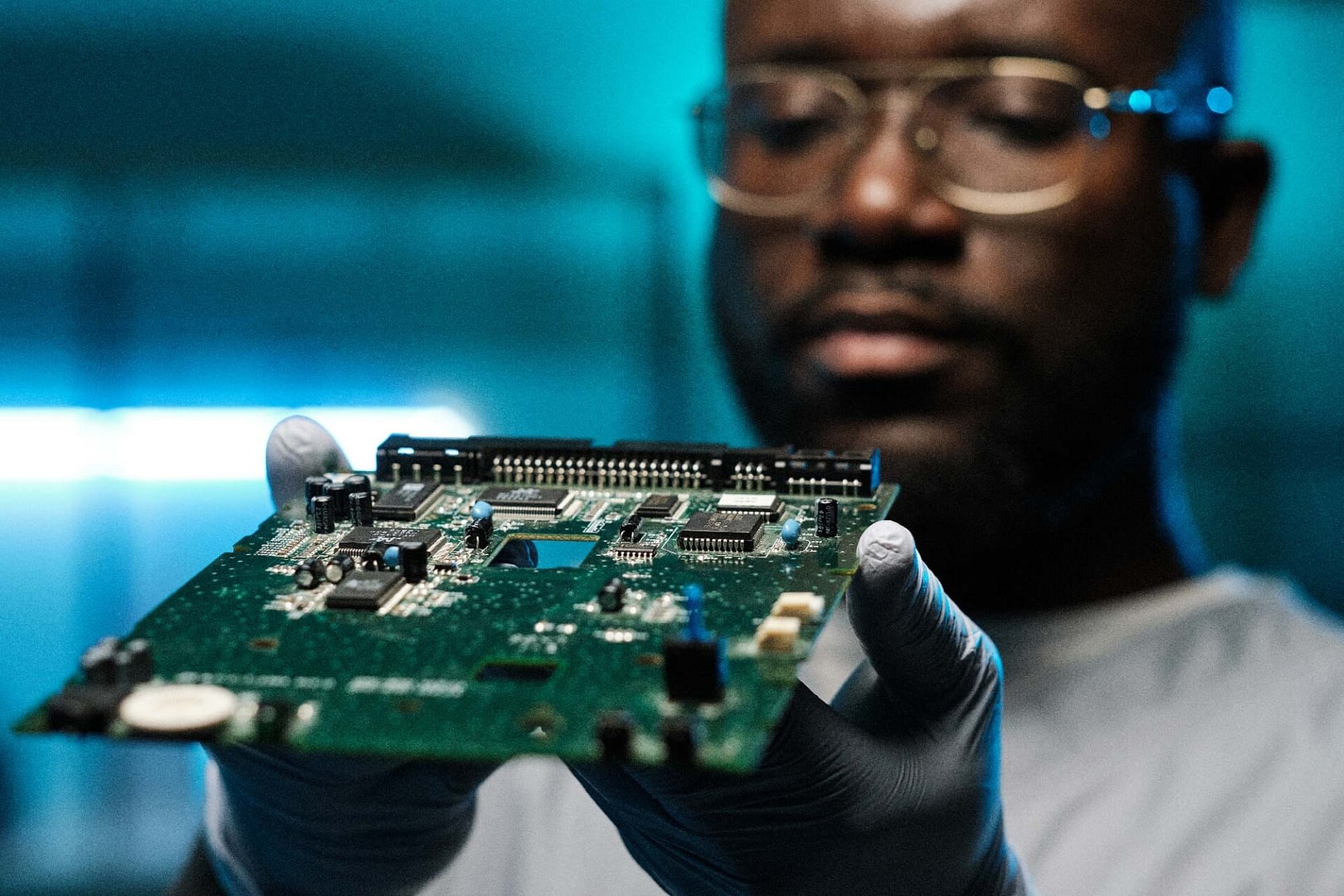

Press-fitting of connectors and micro-components on printed circuit boards (PCBs).

Precision assembly of prosthetics and surgical tools, ensuring biocompatibility and structural integrity.

At GAV Sistemi, we analyze each production requirement and provide fully customized press fitting solutions. Our process includes:

Every press fitting solution is designed for maximum reliability, accuracy, and efficiency, ensuring consistent results for high-volume and precision assembly environments.

A Laser Marking system can be configured to handle a wide variety of tasks, typically involving high precision and repeatability. GAV Sistemi’s systems often integrate several of the following operations in a single, compact setup:

Learn about all the new and exciting leaps in automation we’re making.

© GAV Sistemi S.r.l. - P.IVA 01861100608 - N. REA 106700 - Via Tumuli 4/a , FR 03100 Italy

Built by Dopamina