Imagine a system where permanent, high-precision markings are applied to components or products using advanced laser technology, ensuring traceability and compliance with industry standards.

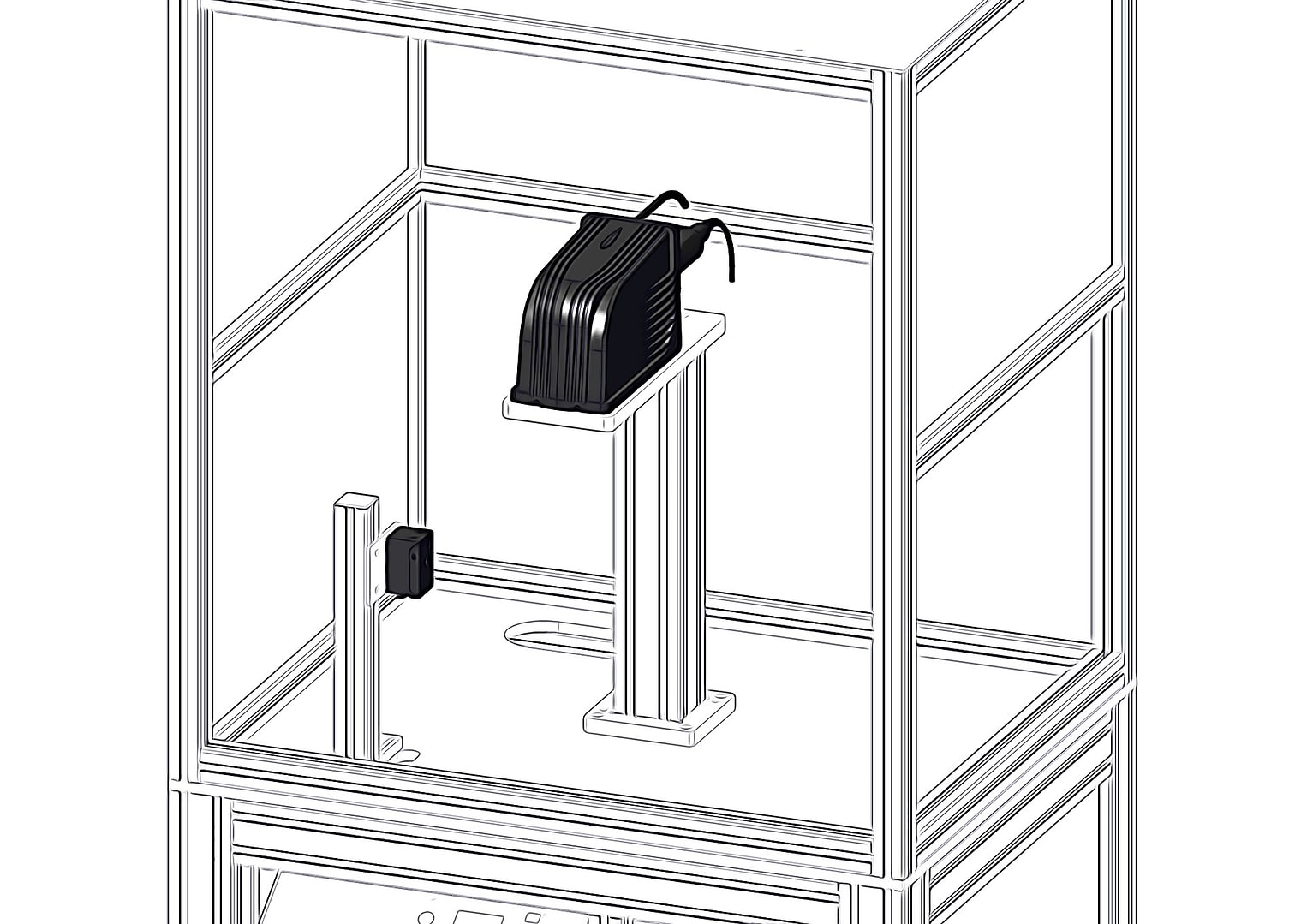

The Laser Marking system is an advanced solution designed to engrave codes, logos, or traceability information onto components and products. This technology ensures permanent, high-quality markings without physical contact, making it ideal for industries that require identification and traceability.

This system eliminates the need for adhesive labels or inks, providing a cost-effective and environmentally friendly solution. According to industry benchmarks, laser marking systems can process materials at high speeds while maintaining exceptional precision, making them suitable for high-volume production lines.

Ensures high-quality engravings on various materials, including metals, plastics, glass, and ceramics

No need for ink or labels, reducing operational costs and environmental impact.

Ideal for production lines with high throughput requirements.

Allows for the engraving of text, QR codes, logos, and serial numbers, enabling full product customization

Eliminates the risk of damage to delicate components during marking.

Integration with ERP systems for automated serialization and data synchronization

Meets international safety standards for laser operation

Ensures compliance with regulatory standards through permanent, machine-readable markings.

The Line with Pallet Conveyors is particularly well-suited for the following industries and applications:

Marking serial numbers on components for traceability

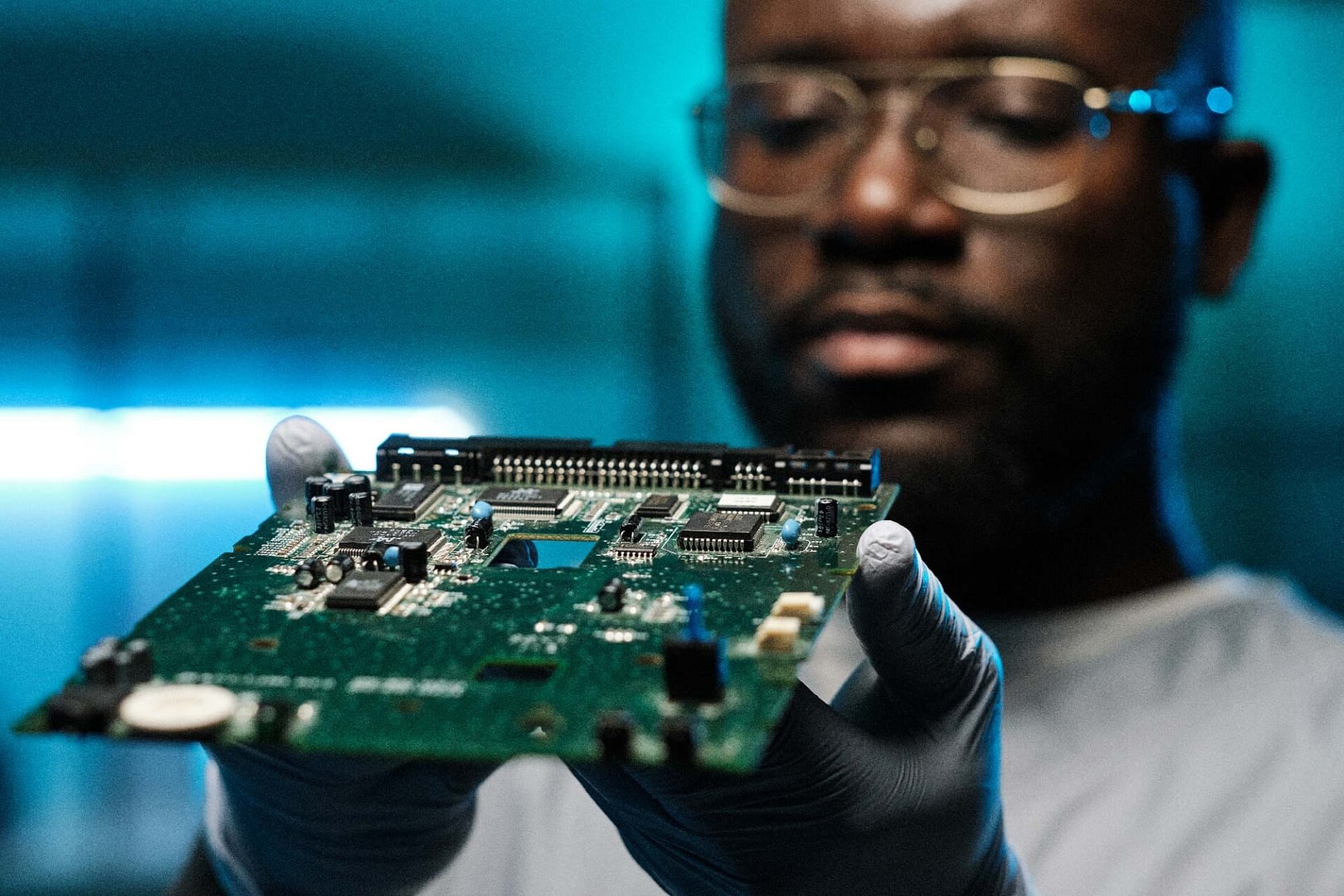

Identification of components on printed circuit boards (PCBs).

Traceability of surgical instruments and medical devices.

Engraving expiration dates and barcodes on packaging materials.

Engraving critical identifiers on precision parts.

At GAV Sistemi, we understand that every production line presents unique challenges. For this reason, every project begins with an in-depth feasibility study aimed at clarifying the specific requirements of the client. This process includes analyzing product dimensions, desired cycle times, quality control demands, and applicable regulatory standards. Our team works closely with you to design customized solutions that integrate seamlessly into your existing workflows, ensuring maximum efficiency and tangible results.

Below are the key points that guide the design of our solutions, reflecting our commitment to innovation, quality, and sustainability:

A Laser Marking system can be configured to handle a wide variety of tasks, typically involving high precision and repeatability. GAV Sistemi’s systems often integrate several of the following operations in a single, compact setup:

Learn about all the new and exciting leaps in automation we’re making.

© GAV Sistemi S.r.l. - P.IVA 01861100608 - N. REA 106700 - Via Tumuli 4/a , FR 03100 Italy

Built by Dopamina