Imagine a fully automated system where screws and bolts are tightened with unparalleled precision, ensuring consistent quality and reducing the risk of human error.

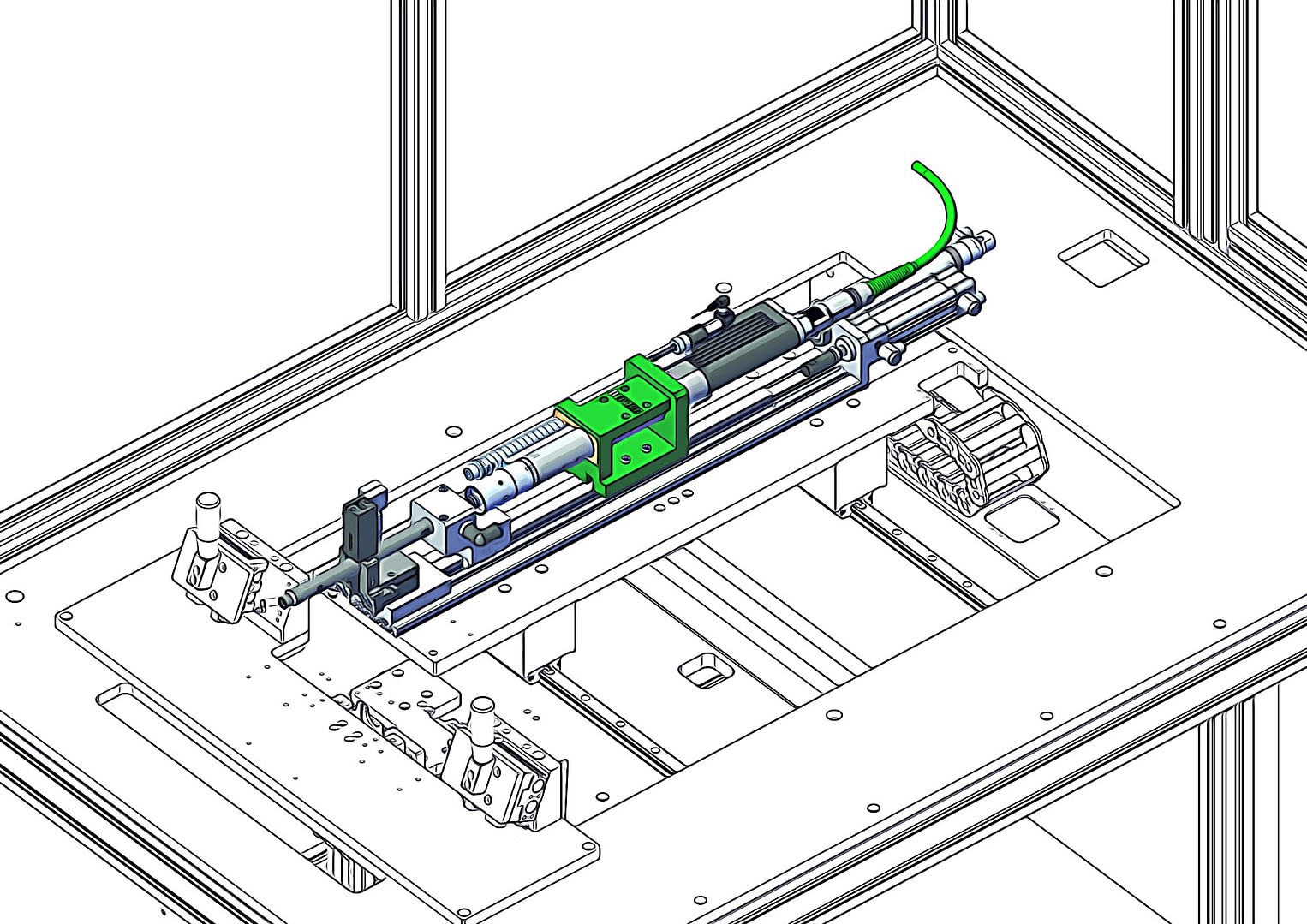

The Screwdriver Machine is an advanced, fully automated solution designed for the precise tightening of screws and bolts. This machine ensures high repeatability, speed, and accuracy in the fastening process, making it essential for industrial assembly lines. By eliminating human variability, the Screwdriver Machine reduces production time, improves product quality, and minimizes errors such as over-tightening or under-tightening.

This system is engineered to meet the stringent requirements of industries like automotive, electronics, and aerospace, where precision and reliability are critical. According to industry benchmarks, automated screwdriving systems can reduce assembly time by up to 30% compared to manual processes

Ensures accurate torque and depth control for uniform and reliable fastening.

Reduces assembly times significantly compared to manual screwdriving.

Minimizes errors, damage, and defects during the fastening process.

Records real-time data for quality verification and reduces scrap rates.

Can be integrated into larger automated workflows, allowing for seamless scalability.

Includes isolation mechanisms to protect operators during operation.

Reduces the need for direct labor, lowering production costs.

Sensors enable real-time monitoring and predictive maintenance, reducing downtime.

The Robot Station is particularly well-suited for the following industries and applications:

Assembly of engines, electronic components, and dashboards.

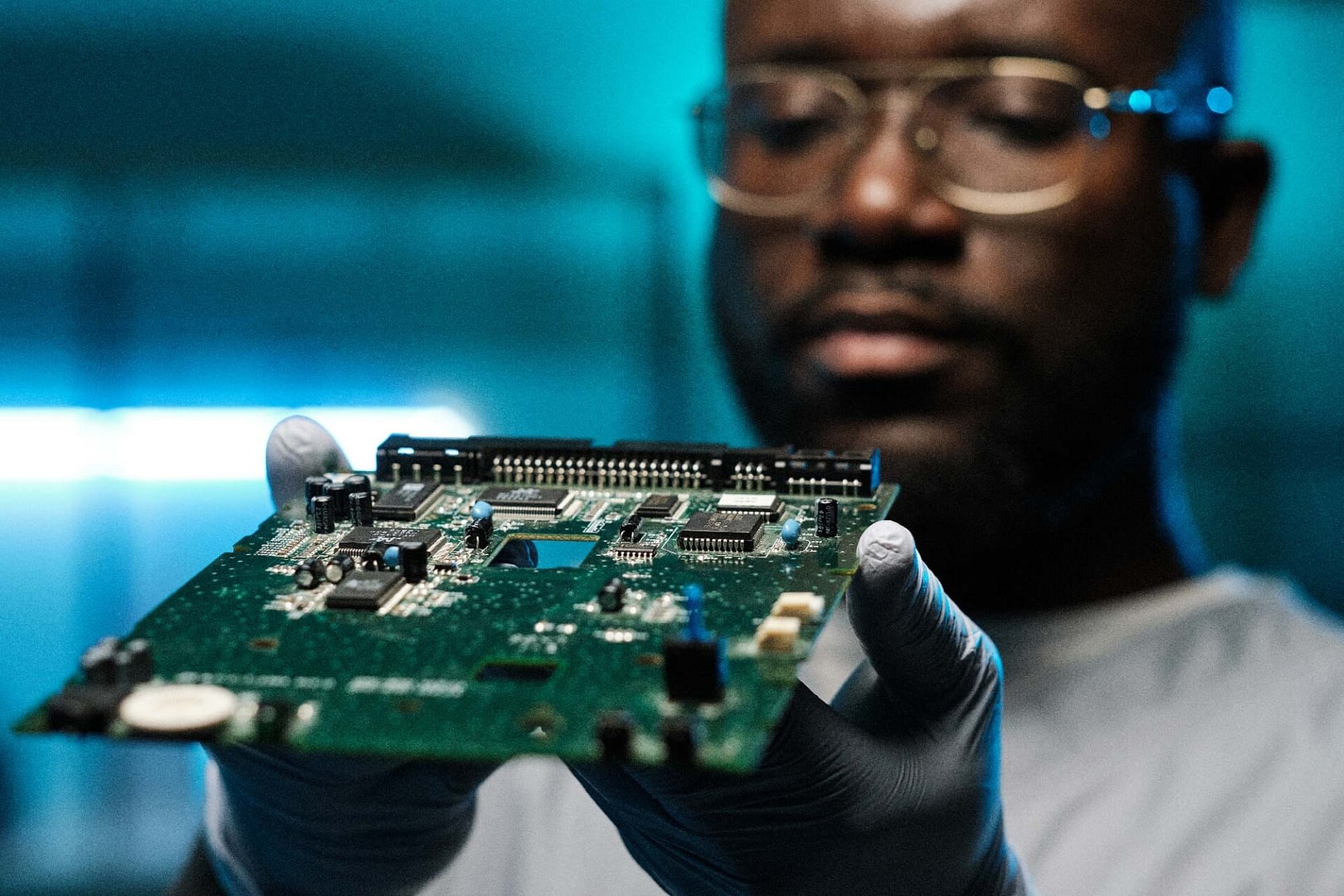

Fastening printed circuit boards (PCBs), chassis, and connectors.

Assembly of medical devices and prosthetics requiring high precision.

Assembly of panels, internal structures, and external components.

Mounting of structural components with strict adherence to safety standards.

At GAV Sistemi, we understand that every production line presents unique challenges. For this reason, every project begins with an in-depth feasibility study aimed at clarifying the specific requirements of the client. This process includes analyzing product dimensions, desired cycle times, quality control demands, and applicable regulatory standards. Our team works closely with you to design customized solutions that integrate seamlessly into your existing workflows, ensuring maximum efficiency and tangible results.

Below are the key points that guide the design of our solutions, reflecting our commitment to innovation, quality, and sustainability:

A Screwdriver Machine can be configured to handle a wide variety of tasks, typically involving high precision and repeatability. GAV Sistemi’s systems often integrate several of the following operations in a single, compact setup:

Learn about all the new and exciting leaps in automation we’re making.

© GAV Sistemi S.r.l. - P.IVA 01861100608 - N. REA 106700 - Via Tumuli 4/a , FR 03100 Italy

Built by Dopamina