Advanced systems designed to ensure reliability, compliance, and precision in quality control processes.

In industries where precision and compliance are critical, automation has become a key factor in achieving consistent quality and operational excellence. Automation in quality control minimizes human error, enhances accuracy, and ensures that every product meets rigorous standards before reaching the market.

Automated quality control systems are designed to detect even the smallest defects that are often overlooked by manual inspection. By utilizing advanced imaging technologies, sensors, and AI-driven algorithms, these systems ensure a level of precision that is impossible to achieve manually.

Automation accelerates quality control processes by integrating high-speed inspection systems into production lines. These systems can inspect multiple components simultaneously without interrupting workflow, significantly reducing cycle times and boosting overall efficiency.

In industries where safety and quality standards are stringent, automated systems ensure that every product complies with industry regulations and certifications. These systems provide reliable and repeatable testing processes, guaranteeing that products meet all necessary legal and safety requirements.

Quality Control Automation refers to the integration of advanced technologies, robotics, and software systems into the processes of inspecting, testing, and verifying products. This automation minimizes human error, enhances accuracy, and ensures consistent quality throughout production. By implementing automated quality control systems, manufacturers can meet stringent industry standards, reduce waste, and optimize their operations.

Automation plays a pivotal role in industries where precision and compliance are non-negotiable, such as automotive, electronics, and medical devices. Through technologies like vision systems, automated testing, and real-time analytics, quality control automation provides a reliable framework for delivering products that meet the highest standards.

Our solutions reset the standard

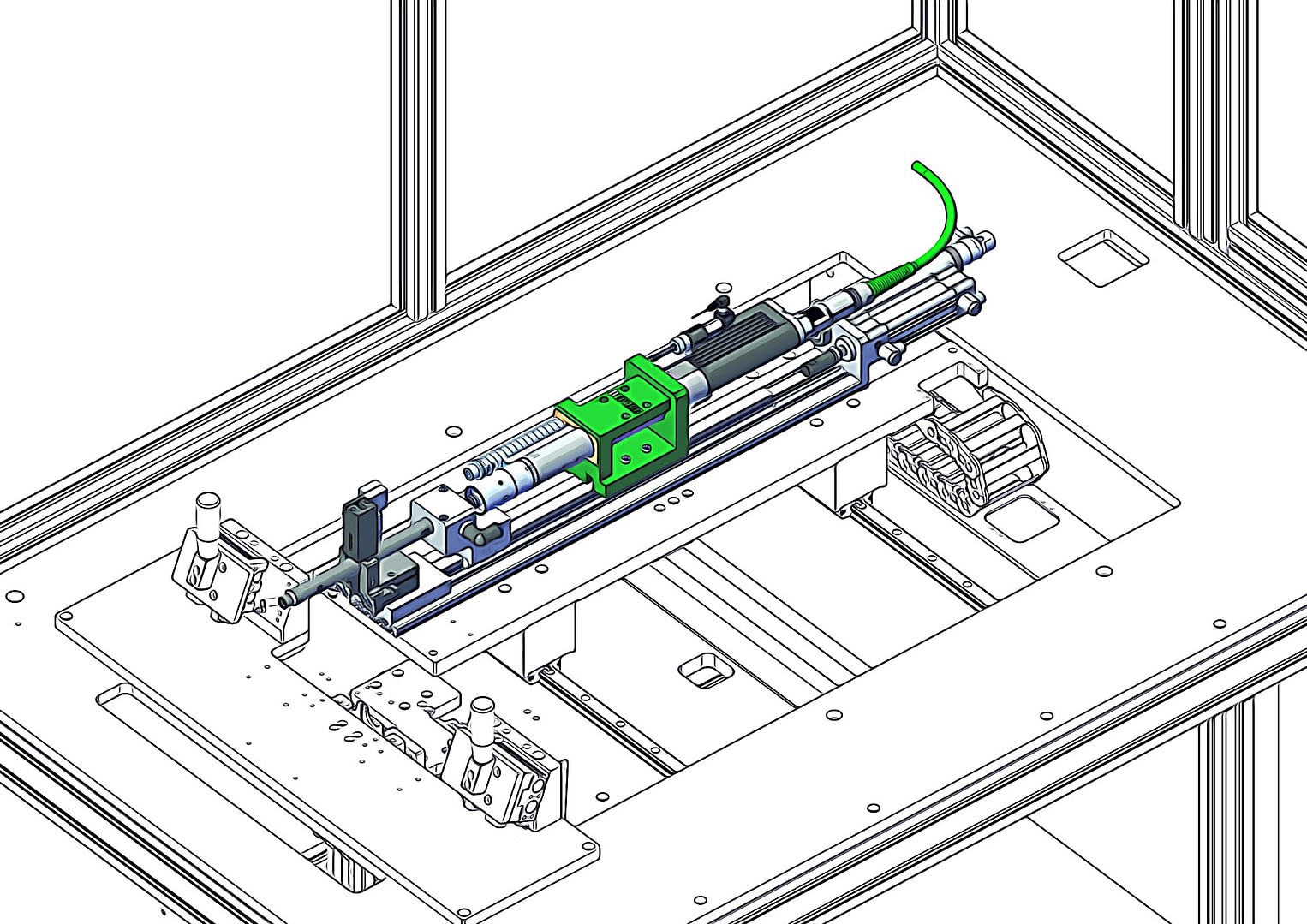

High-speed inspection and validation system using advanced sensors to detect defects and ensure quality compliance in various manufacturing processes.

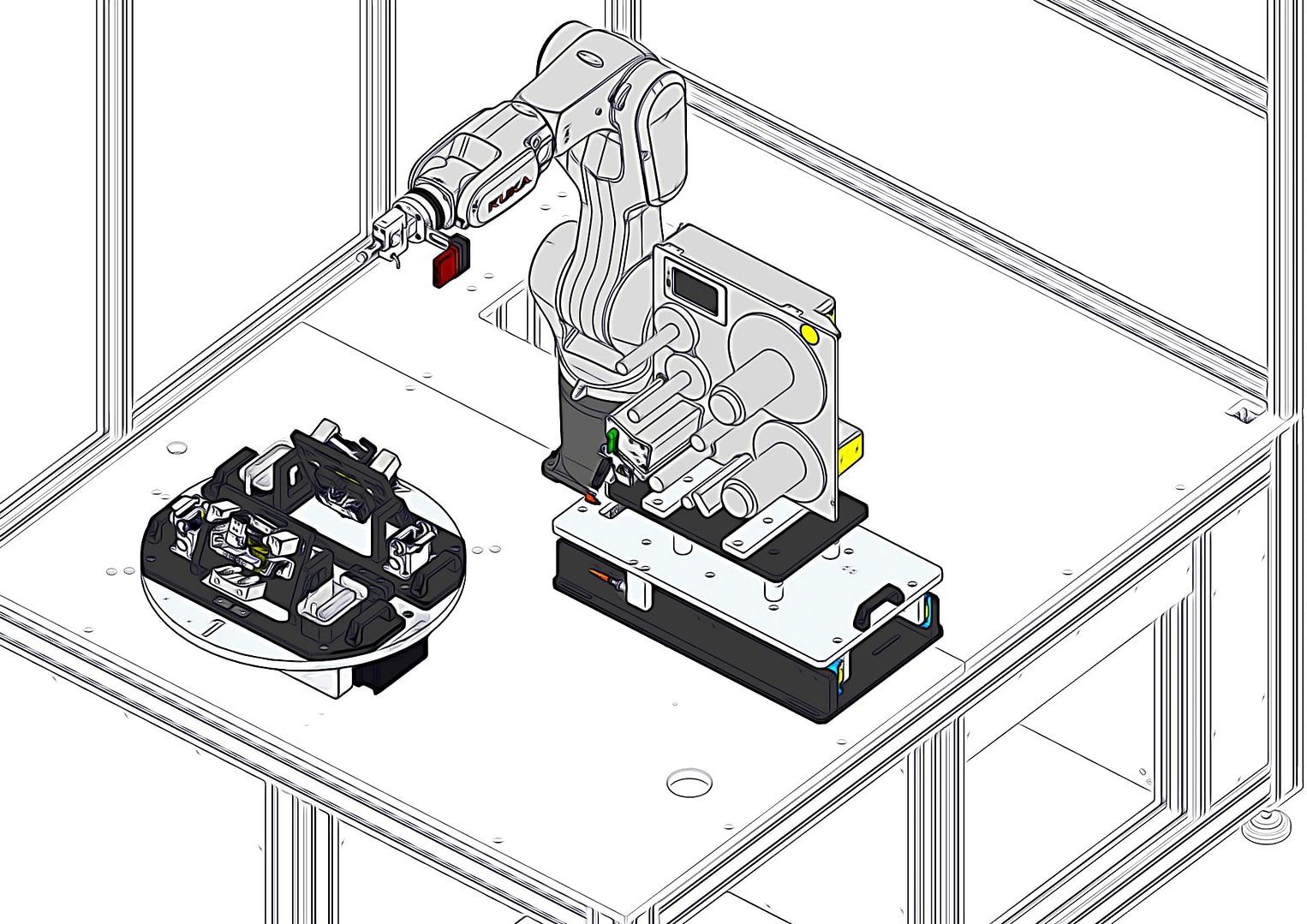

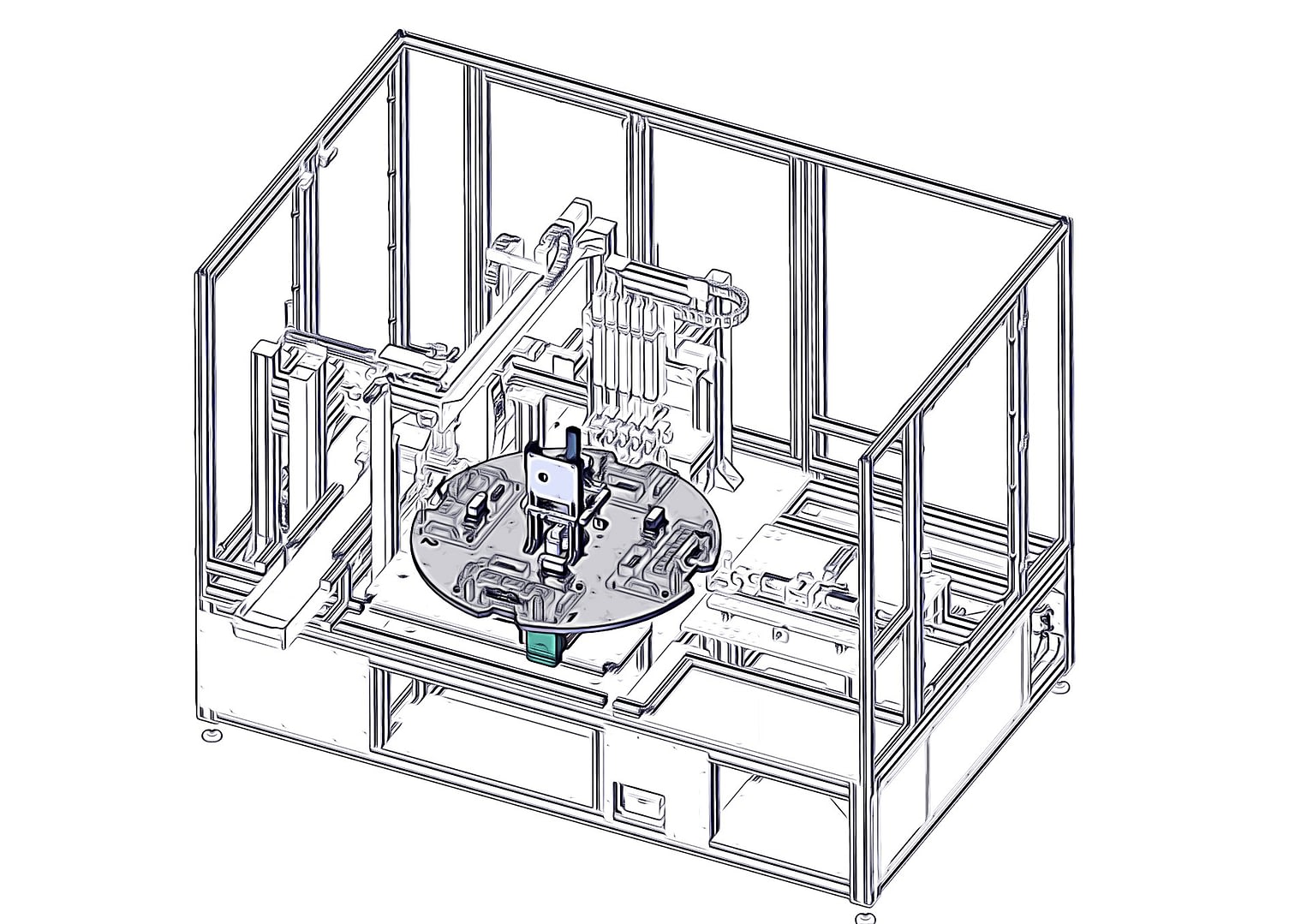

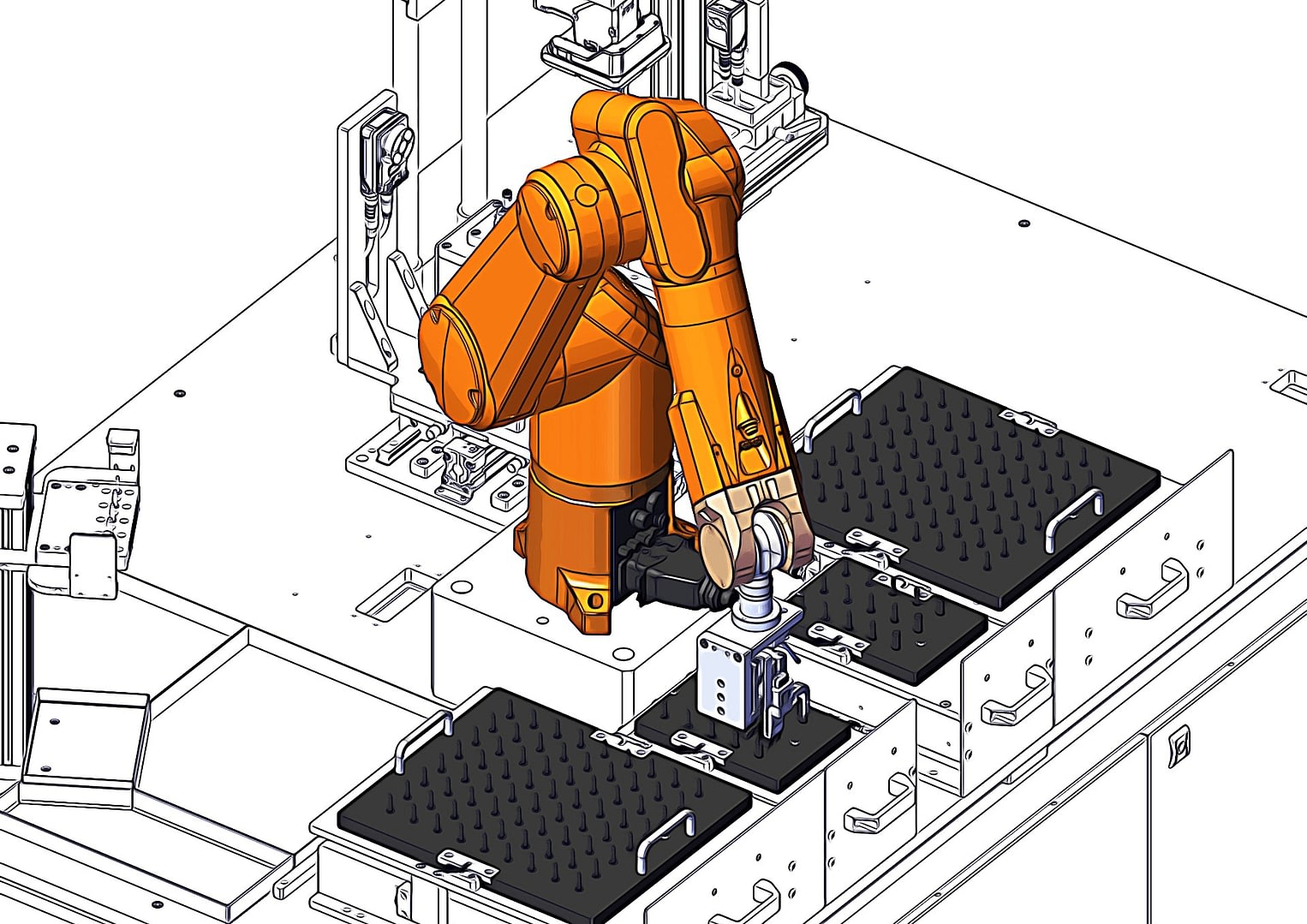

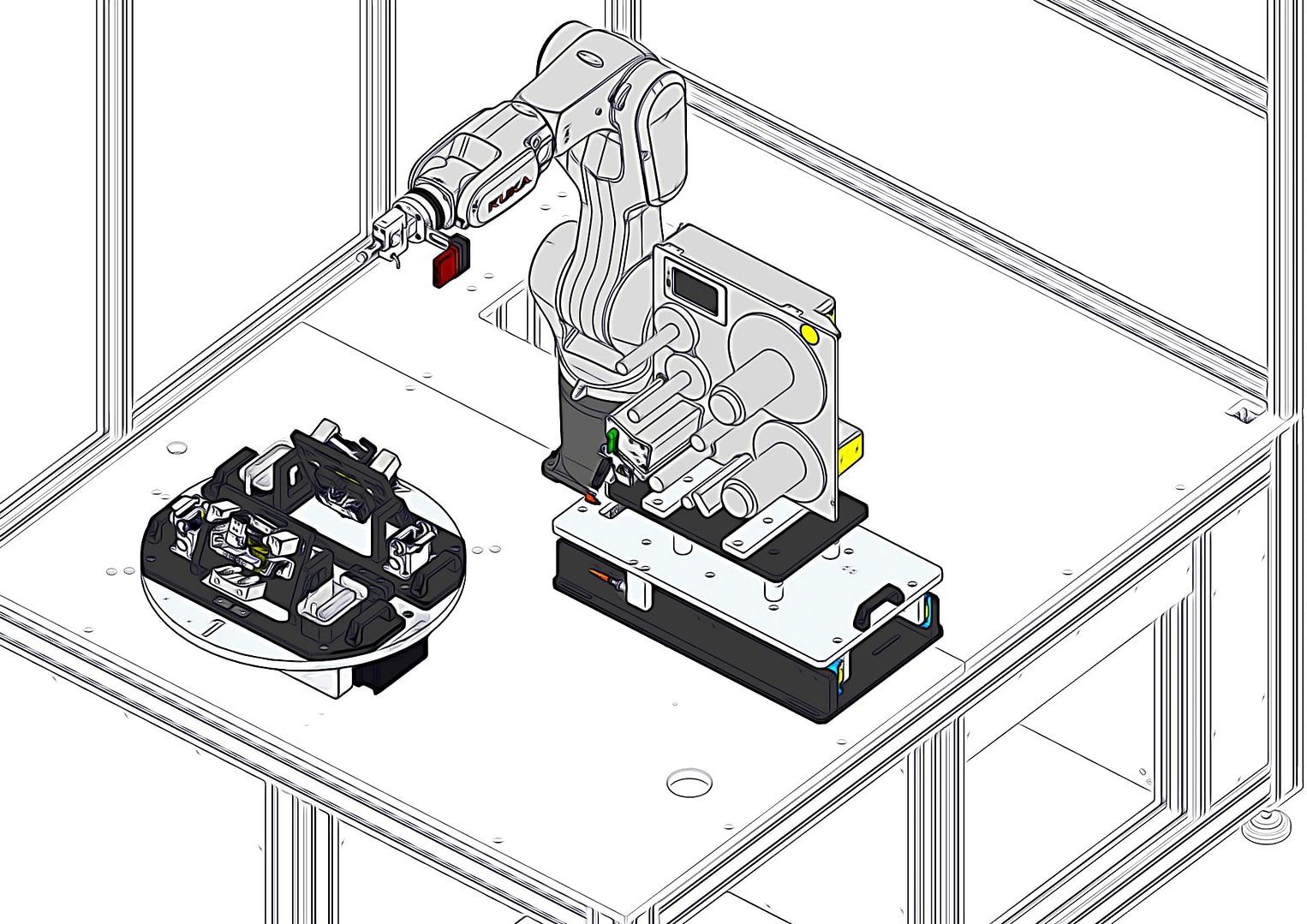

Robotic workstations for precision inspection, dimensional verification, and defect detection in automotive, electronics, and industrial applications.

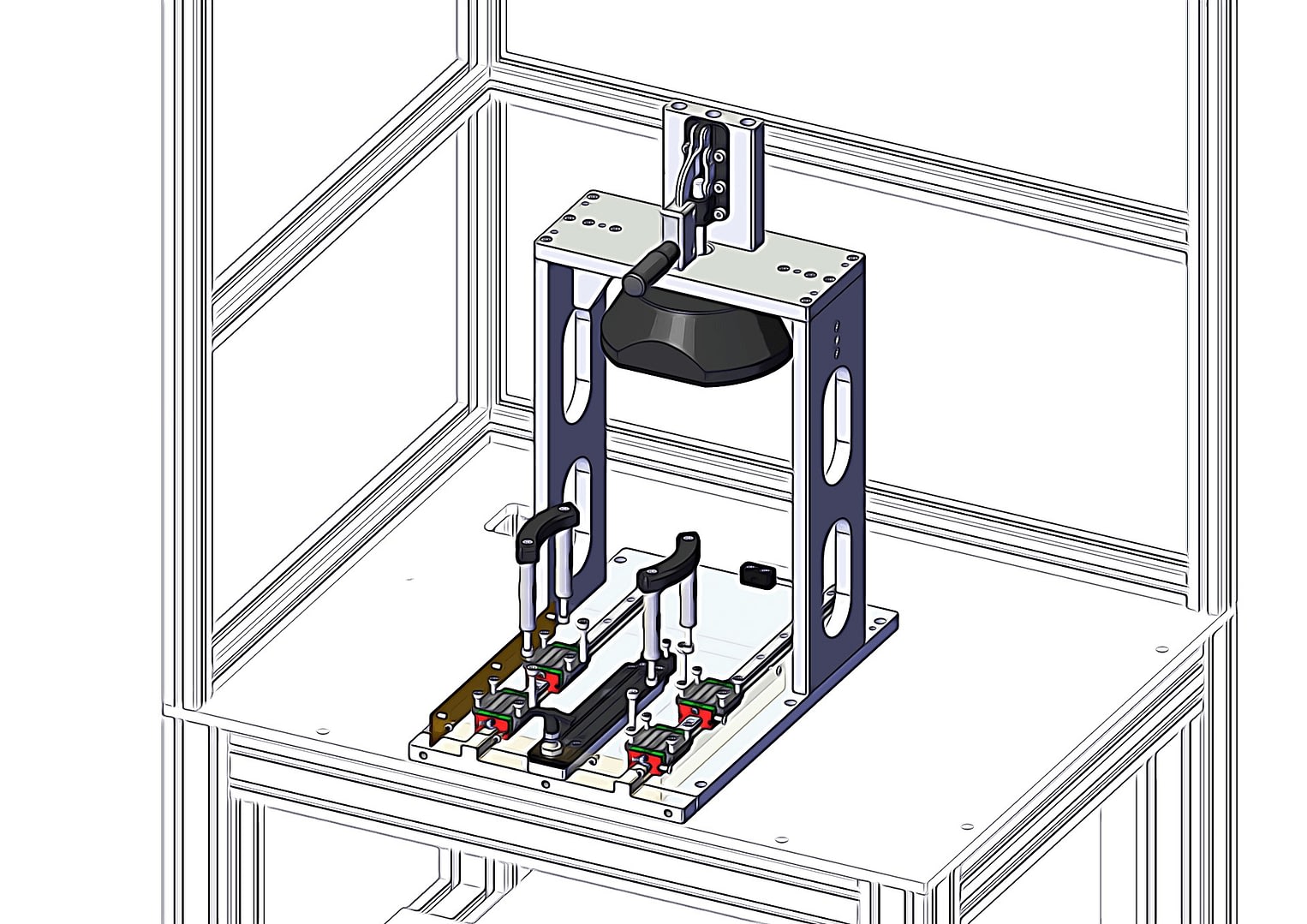

Precision screwdriving system with force and torque monitoring, ensuring secure fastening and reducing assembly errors in production lines.

AI-powered vision inspection and measurement systems for real-time detection of surface defects, missing parts, and non-conformities.

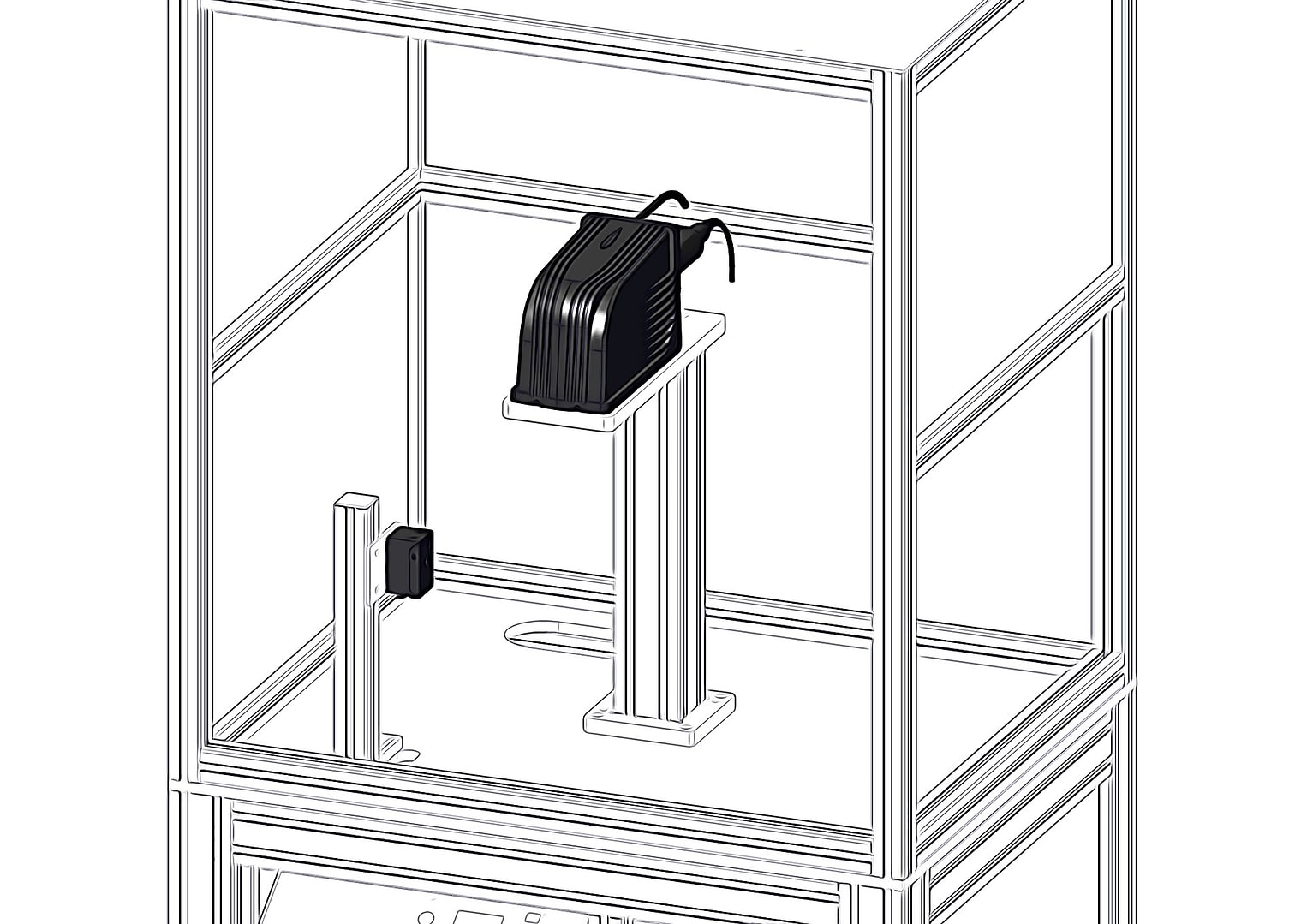

High-sensitivity leak detection system for micro-leak identification in sealed components, ensuring compliance with industry regulations.

Traceability and product identification solutions with laser engraving for electronics, medical devices, and high-precision components.

AI-assisted robotic inspection systems for fast and accurate defect detection, improving quality control efficiency and precision.

Learn about all the new and exciting leaps in automation we’re making.

© GAV Sistemi S.r.l. - P.IVA 01861100608 - N. REA 106700 - Via Tumuli 4/a , FR 03100 Italy

Built by Dopamina