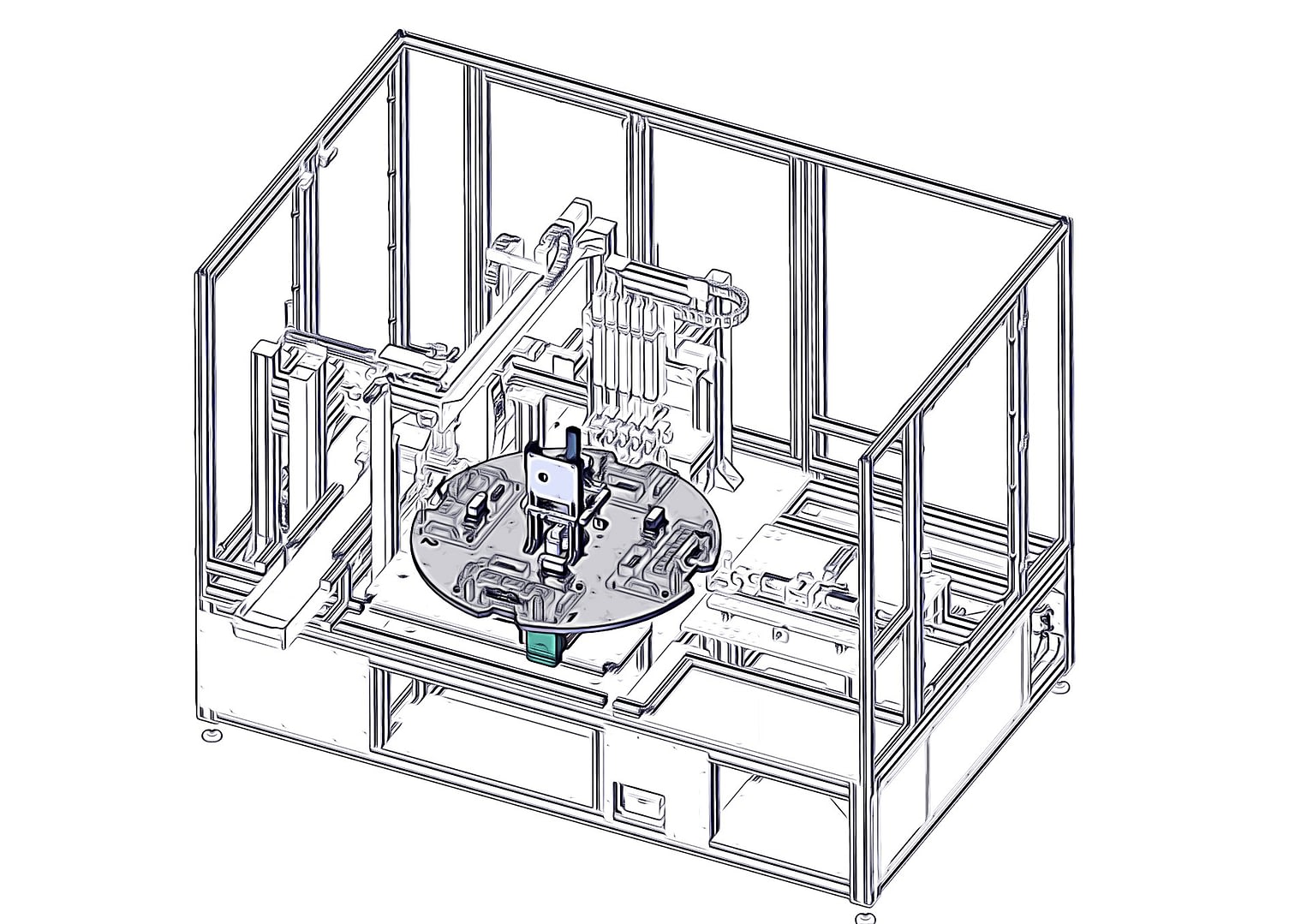

Imagine an automated system where multiple tasks—such as assembly, inspection, or part transfer—take place in a seamless rotation on a single, compact platform.

A rotary machine is an automated system with a centrally driven turntable equipped with workstations arranged in a circular layout. This system rotates through defined angular increments, presenting each part to various stations with minimal downtime. According to the International Federation of Robotics (IFR), indexed rotary systems often outperform linear systems in throughput and repeatability, especially when consistent positioning and high speed are top priorities 2.

The rotary machine is designed to perform up to four different operations simultaneously with a single operator, ensuring continuous workflow without interruptions. This makes it ideal for industries that demand high productivity, precision, and reduced labor costs.

Executes operations with superior speed and precision compared to manual processes.

Reduces the need for direct labor, lowering production costs.

Achieves high precision through advanced sensors and automated controls.

Integrates a system for real-time parameter control and data recording.

Compact configuration compared to traditional production lines.

Includes isolation mechanisms to protect operators during operation.

Ensures accurate mechanical control for high-quality processing.

Allows the addition of modules with diverse functions to adapt to new needs.

Can be connected to existing production lines without significant modifications.

While the Rotary Indexing Machine is particularly well-suited to the automotive domain—for example, integrating seamlessly into chassis welding or component assembly lines—it also excels in:

Assembly of airbags, components, and powertrain systems.

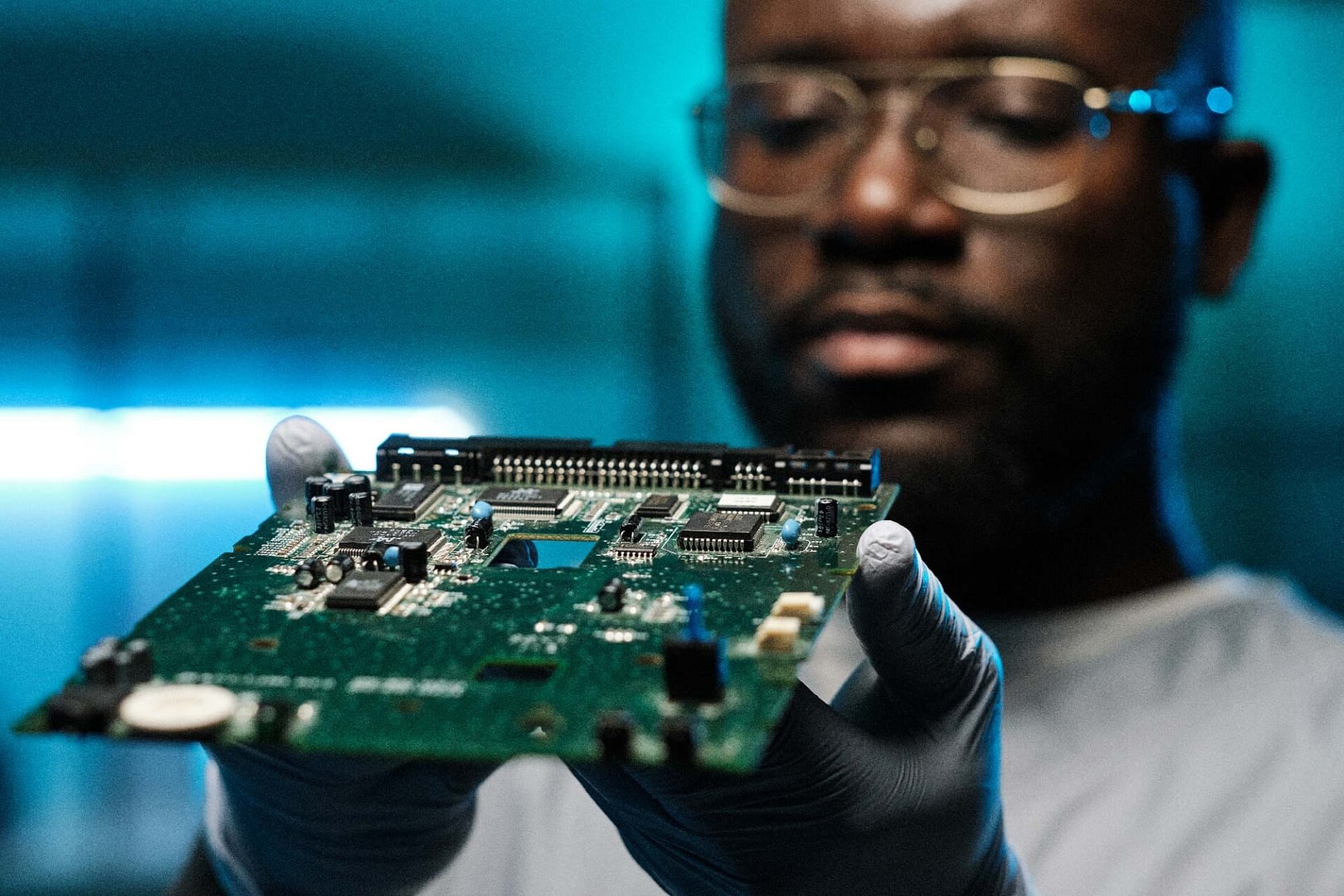

Soldering, circuit board assembly, and connector insertion.

Production of syringes, catheters, and drug delivery systems with strict adherence to sterility and traceability.

Filling, capping, labeling, and sealing processes in a compact space.

Precision machining and assembly of aerodynamic components.

At GAV Sistemi, we understand that every production line presents unique challenges. For this reason, every project begins with an in-depth feasibility study aimed at clarifying the specific requirements of the client. This process includes analyzing product dimensions and handling characteristics, desired cycle times, quality control demands, and applicable regulatory standards. Our team works closely with you to design customized solutions that integrate seamlessly into your existing workflows, ensuring maximum efficiency and tangible results.

Below are the key points that guide the design of our solutions, reflecting our commitment to innovation, quality, and sustainability:

A rotary indexing machine can be configured to handle a wide variety of tasks, typically involving high precision and repeatability. GAV Sistemi’s systems often integrate several of the following operations in a single, compact setup:

Learn about all the new and exciting leaps in automation we’re making.

© GAV Sistemi S.r.l. - P.IVA 01861100608 - N. REA 106700 - Via Tumuli 4/a , FR 03100 Italy

Built by Dopamina